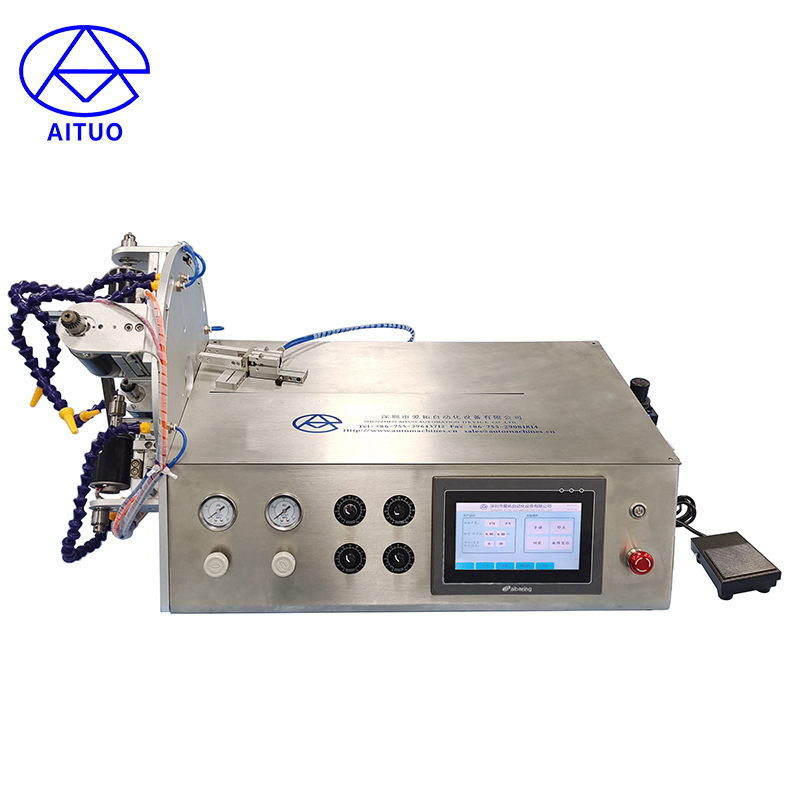

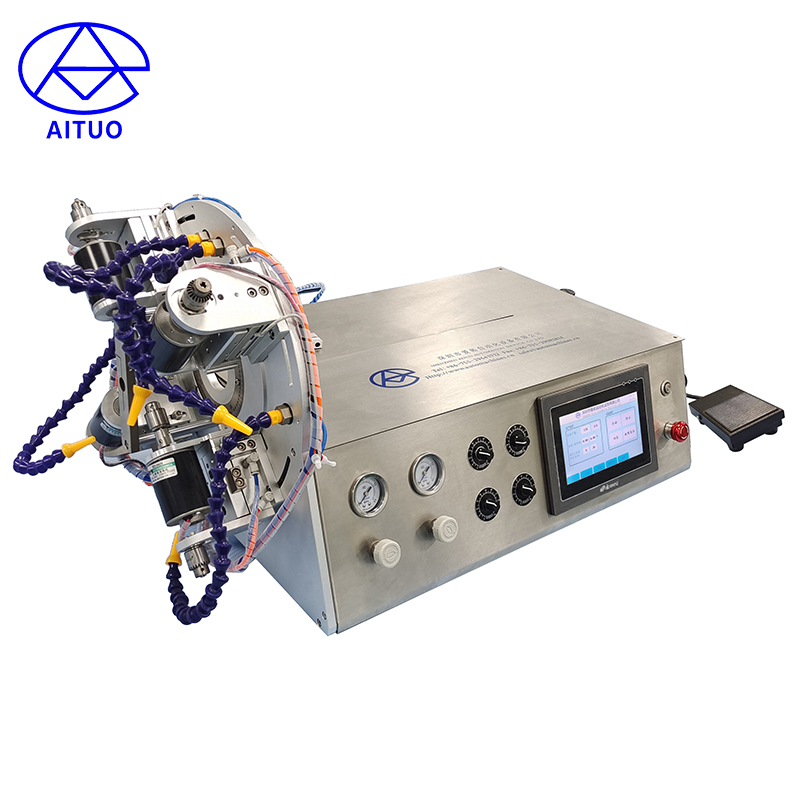

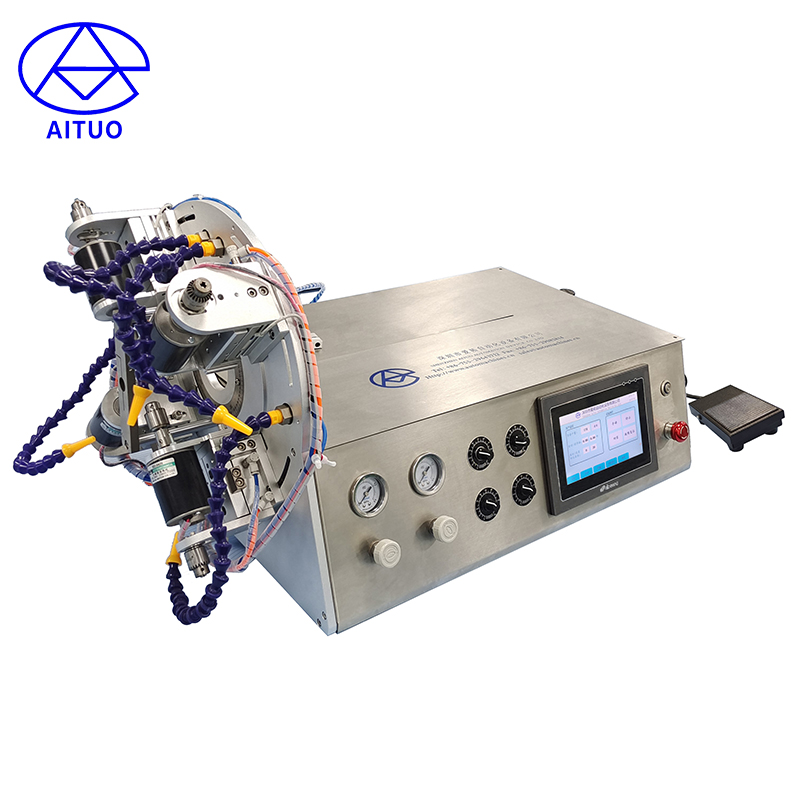

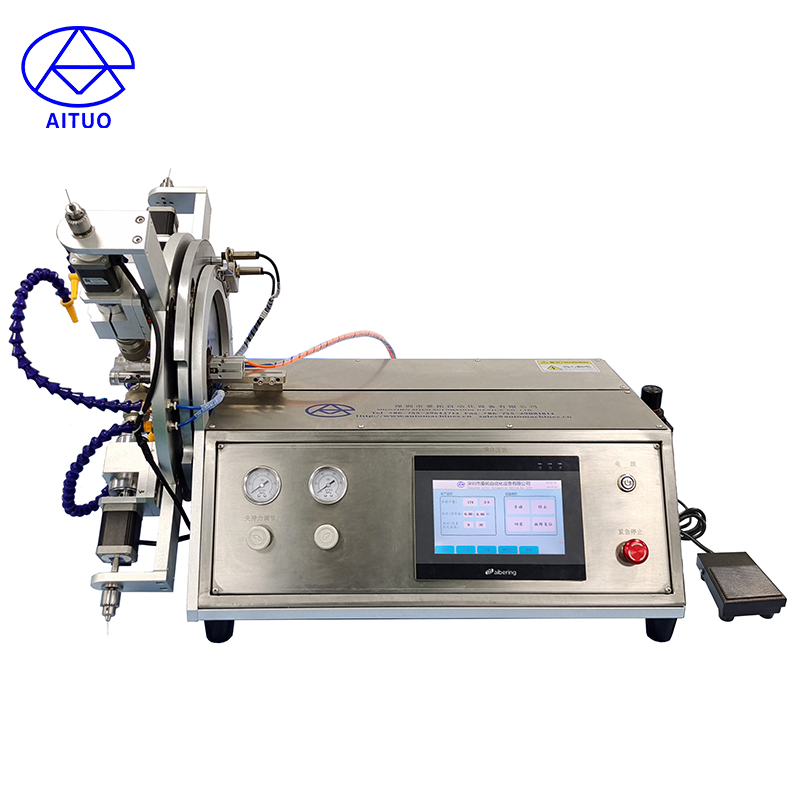

Medical four-axis cnc drilling hole machine AM20107

[Item No.] AM20107

[Upper Material] Metal

[Outsole Material] Metal

[Sizes] 740*420*400MM

[Color] white/black/

×Enter your message

Product Description

1.Equipment Introduction:

It is mainly used for drilling medical plastic catheters.It is manually discharged and consists of clamping,handling and four-way punching unit.It has a compact structure. The tool holder adopts a 4-way spindle drilling.Equipped with reset ejection structure, the waste is ejected from the blade when resetting.Punching stroke, number of punches and distance between punches can be freely adjusted.Punching angle is a fixed 90 degrees.

2.Equipment parameters:

Working power: AC 220V, 10A, 50HZ

Air pressure: 0.5-0.8 Mpa

Power: 0.4 Kw

Ambient temperature:-20℃ +50℃

Operator: 1 person

Machine punching speed: single axis 2 seconds per hole, 4 axis 2 seconds per 4 holes (using cam drive, four-axis synchronous punching method, according to different material to comment

Weight: 35 KG

Equipment size: 740 x 420 x 400 mm (L x W x H)

3.Technical parameters:

Clamping stroke: 400 mm (customisable)

Feeding speed: digitally adjustable up to 100 mm/s

Punch spacing: CNC adjustable

Adjustment accuracy: ±0.02 mm

Motorised spindle speed: 0 to 3000 RPM (digital setting)

Motorised spindle runout: s±0.03 mm

Z-axis module accuracy: ±0.02 mm

Hole diameter machining range: 0.3-8 mm

Catheter diameter processing range: 6.0-20.0 mm

Applicable materials: PVC, PU, HDPE, LDPE, PP, PA, PEBAX, FEP, etc.

Prev: what is CVC catheter?