Medical pad printing catheter processing machine

Steel plate size: 100*100mm

Printing area: 70*70mm

Printing speed: 1500times/h

Machine dimension: 410*600*1200mm

Weight: 65 kg

Air pressure: 5 bar

Power supply: 110/220V 50W

×Enter your message

Product Description

Medical device pad printing machine

Medical Catheters Pad printing machine

Machine name: Small monochrome printing machine

Steel plate size: 100*100mm

Printing area: 70*70mm

Printing speed: 1500times/h

Machine dimension: 410*600*1200mm

Weight: 65 kg

Air pressure: 5 bar

Power supply: 110/220V 50W

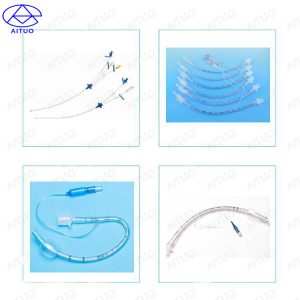

Scope of application

Small monochrome printing machine are more suitable for printing small area products. It has a wide range of applications, such as printing earplugs, USB, MP3, MP4 and other products with company logos or patterns. All-cast aluminum body, vertical structure, simple installation procedure, convenient operation, fast printing speed up to 1200~1500 times/hour. Widen the oil pan to obtain a large printing area, suitable for the surface pattern logo printing of electronic products, plastic shells, hardware products, stationery, small crafts, and gifts.

Catheter Pad Printing Systems

Product performance

- It has automatic computer control, flexible and reliable operating procedures.

- As to the machine printing head,it can adjust and raise to facilitate the replacement of ink, plastic head, steel plate and parts.

- It can chang freely to multi-color printing for the ink tray and printing head , which breaks through the general mechanical performance and adds more flexibility.

- The X and Y angles of each oil pan seat are adjusted independently, the color registration is accurate, and the production efficiency is high.

- The machine body adopts aluminum alloy die-casting frame, which is both portableand stable.

- Use Japanese (SMC) pneumatic components to cooperate with CNC machine tools for processing.

- The hardened shafts and bearings of famous factories are selected to ensure that maintenance is reduced and not easy to wear, and the life of the parts is greatly extended.

- The automatic scraper system can adopt nylon plate or steel plate, which is easy to adjust.

- Equipped with rubber sheet and power emergency cut-off system, in line with industry standards.

- The large printing area that can be obtained by widening theink tray: 300*120mm.