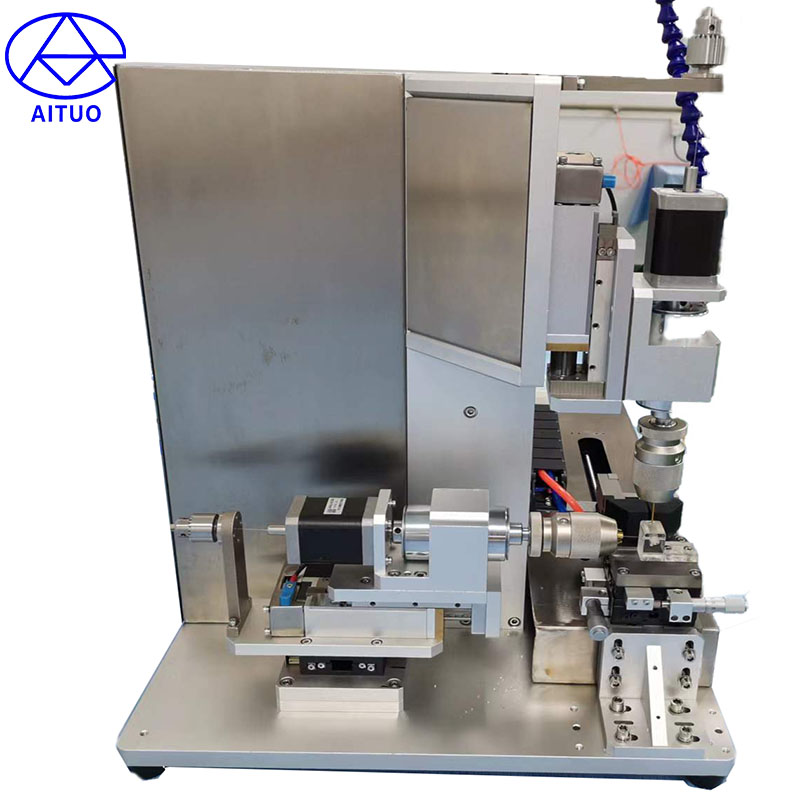

AM20106 Rotary twin spindle CNC drilling machine

Working power supply: AC 220V 50Hz

Working air pressure: 0.4-0.8 Mpa

Total power of the equipment: 0.5 KW

Ambient temperature: -20℃+50℃

Machine punching speed: 500-1200 PCS/H (to be assessed according to different material )

Machine weight: 30 KG

Equipment size: 650 x 420 x 493 mm (L x W x H)

×Enter your message

Product Description

AM20106 Rotary twin spindle CNC drilling machine

It is a full CNC double axis punching machine, mainly used for medical plastic catheter punching.It is manually discharged and consists of three machining axes: electric trimmer stage (horizontal X-axis), precision electric slide cylinder (horizontal Y-axis) and Z-axis precision electric slide cylinder (vertical direction).The machining axes work in conjunction with the tube rotation axis (R-axis) and the tube pull-in axis to drill the tube at any angle and size, providing fast response times and high stability.The tool holder is equipped with an imported heavy-duty self-locking chuck and a reset ejector mechanism, which allows the waste to be ejected from the tool when it is reset. The drilling angle and the distance between the two knives can be adjusted at will.

Equipment parameters

Working power supply: AC 220V 50Hz

Working air pressure: 0.4-0.8 Mpa

Total power of the equipment: 0.5 KW

Ambient temperature: -20℃+50℃

Machine punching speed: 500-1200 PCS/H (to be assessed according to different material )

Machine weight: 30 KG

Equipment size: 650 x 420 x 493 mm (L x W x H)

Technical parameters

1. X-axis

X-axis adjustable range: 0-20 mm (intersecting 90° axial hole pitch adjustable range)

X-axis adjustment resolution: 5 um

2. Y-axis

Y-axis stroke: max. 50 mm (digital setting of stroke)

Y-axis stroke resolution: 10 um

Y-axis thrust: 80 Nm

Y-axis punching spindle speed: 0-3000 RPM (digital setting)

Y-axis punching spindle torque: 0.4 Nm

Y-axis punching spindle runout: ±0.02 mm

3. Z-axis

Z-axis strokel: max. 50 mm (digital setting of stroke)

Z-axis stroke resolution: 10 um

Z-axis thrust: 80 Nm

Z-axis punching spindle speed: 0-3000 RPM (digital setting)

Z-axis punching spindle torque: 0.4 Nm

Z-axis punching spindle runout: ±0.02 mm

4. R-axis

R-axis stroke: 0-360 degrees (digital setting)

R-axis stroke resolution: ±0.5 degrees

R-axis speed: 0-1000 RPM (digital setting)

R-axis torque: 0.16 NM5. L axis

L-axis stroke: 300 mm

L-axis repeat positioning accuracy:±0.02 mm

L-axis maximum speed: <500 mm/s

6. Range of application

Hole diameter processing range:0.3-5 mm (customizable)

Catheter diameter processing range;3F-32F (1-11mm, customizable)

Applicable materials: PVC PU HDPE LDPE PP PA PEBAX FEP PS TPU PTEE etc.

Video: